Sollant Rotary Screw

Air Compressor

Your one-stop solutions supplier of screw air compressor

Rotary Screw Air Compressor Manufacturer and Supplier

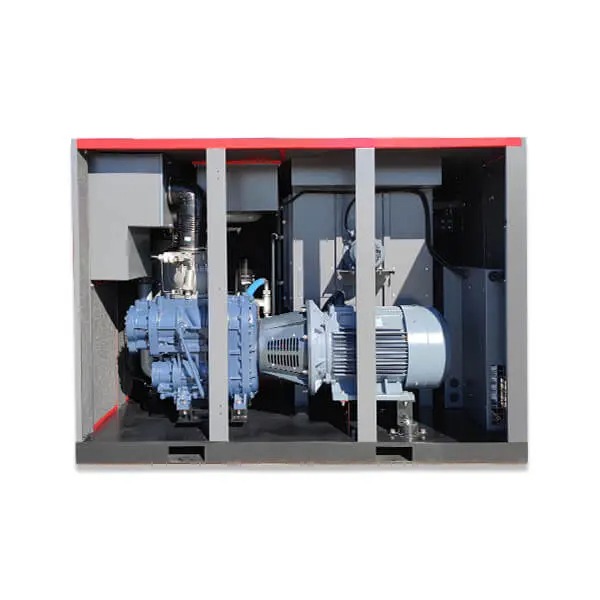

As an important form of energy generation, the rotary screw air compressor is widely used in all aspects of life and production. Sollant rotary screw air compressor is durable and its appearance is made of high-quality cold-rolled steel plate cover. It adopts a spray molding process and high temperature baking at 250 ° C. It is corrosion-resistant and durable for a long time.

The rotary screw air compressor components of the electrical appliance are the components of the world-famous brand Schneider Electric/ABB, with silver contacts, the service life is more than 3 million times, and the safe use is guaranteed for a long time. The bearings are imported from Switzerland, which better improves the use efficiency of the host machine, reduces wear and helps increase the smoothness of the meshing.

Leading Rotary Screw Air Compressor Manufacturer

Develop Your Business with Sollant

Rotary Screw Air Compressor

A rotary screw air compressor is a type of gas compressor, such as an air compressor, that uses a rotary-type positive-displacement mechanism. The gas compression process of a rotary screw is a continuous sweeping motion, so there is very little pulsation or surging of flow, as occurs with piston compressors.

Rotary screw air compressors operate by trapping air between two meshed rotors and reducing the volume of that trapped air as it moves down through the rotors. This reduction in volume results in compressed air, which can then be used to power air tools, inflate tires, or in numerous other application.

Why Choose Sollant Rotary Screw Air Compressor?

Sollant rotary screw air compressor,has unique design concept and better quality assurance.

- Its system has the design advantage of small size.

- Low cost but high quality with long service life.

- They are easier to maintain and repair.

- Lower noise of rotary screw air compressor operation.

- Few parts, easy assembly for clients.

- Sollant’s rotary screw air compressor does not leak oil.

Become an Expert When Importing

Rotary Screw Air Compressor From China

Keep us Update on Latest Air Compressor Newsletter

Air Compressor for Laser Cutting

Table of Contents

Introduction to Rotary Screw Air Screw Compressor

When it comes to an air compressor, what is the first thing that comes into your mind?

To most of us, the first thing that will come into our mind is a device that forces a stream of air to pass through a small space.

Some people even call them piston compressors since they use pistons to control the movement of air.

The air is then collected on the other end of the tank.

So, what about a rotary screw air compressor?

This is a newer and improved version of the air compressor.

The most outstanding feature about them is the rotation. They rotate while pumping a stream of air.

Screw air compressors are considered a replacement of the traditional air compressors.

Are you planning to buy a compressor?

Read on as we guide you on everything you need to know about a rotary screw air compressor for sale.

What is Rotary Screw Air Compressor?

The procedure works by having a focused laser beam go through the material that you are hoping to cut, conveying a precise and smooth completion.

At first, the beam penetrates the material with an opening at the edge, and afterward, the beam is proceeded with from that point.

The laser basically liquefies or melts the material away that it is run over, so it is more similar to dissolving than cutting. This implies it can undoubtedly cut light materials, for example, fabric up to harder metals and gemstones, for example, precious stones.

When using a laser cutter, you can choose either a pulsed beam or a consistent wave beam, with the previous being conveyed in short blasts while the last works persistently.

You can control the beam power, length heat output, and the material you are working with. You can also use a mirror or unique focal point to additionally centre the laser beam.

Laser cutting is a profoundly precise procedure because of this significant level of control that you are offered.

Because of this, cuts with a width as little as 0.1mm can be accomplished when utilizing the procedure.

And that is how a laser cutter works. So, where does the air compressor come in? W

During the laser cutting process, the main function of the compressed air is to expel the molten material.

Since laser beams generate heat, this means that the affected section of the material will melt. The residue will accumulate around the burnt section.

The pressured gas will form a strong jet that will expel the material from the surface.

What Types of Gases are Used in the Air-Assisted Laser cutting Machines?

A rotary screw air compressor is a type of air compressor that works using the principle of rotary displacement mechanism.

This displacement is caused by the movements of two pairs of spiral rotors. As they are displaced, a stream of airflow is created.

This type of air compressor is mainly used in areas where a large volume of high-pressure air is needed. They are a perfect replacement for the piston compressors.

Basically, a rotary screw air compressor operates by trapping a stream of air between its two meshed rotors.

By doing so, it reduces the volume of the trapped air, which is moving downwards on the rotor.

The reduction of air volume leads to compressed air. This air can be used for large-scale applications. However, they are also applicable to small-scale uses.

For a small business, you can get yourself a small screw air pump for sale.

The rotary sweeping motion of the rotary screw ensures that there there is a minimal pulsation, spurts or interruptions.

In other words, the supply of air will be smooth and consistent.

The screw compressor also operates quietly as compared to other types of air compressors.

Quite a good percentage of industrial machines depend on the rotary air compressors for their operations.

Eliminate this device, and the whole production line will come into a standstill.

How a rotary screw air compressor works

Types of Rotary Screw Air Compressor: oil-injected vs Oil-Free Rotary Screw Compressor

There are two main types of air compressors for sale. These are oil-injected rotary air compressor and oil-free air compressor.

As the names suggest, one type uses oil while the other type does not use oil.

Oil-injected rotary screw air compressors have oil on the chamber cylinder and bearings. The purpose of the oil is to provide the much-needed lubrication.

Once the ends of the rotor seals are well-lubricated, the pressure is generated at a very fast rate. This pressure ensures that air is compressed at a single stage.

Oil is then separated before the air exits the system. This is done to prevent any form of lubrication.

The oil is then recycled to the rear end for reuse.

The good thing about oil-injected screw air compressors is they provide high pressure on a continuous basis.

Oil-free rotary air compressor, on the other hand, do not flood the compression chamber with oil. The lubrication is due to the anti-corrosive agents that the bearings come with.

Although this type of rotary screw compressor is quite expensive, you don’t have to worry about the incidences of oil contamination.

For this reason, they are used in sensitive applications such as food and chemical industries.

Power Ratings of Air Compressors

Apart from the two types, that air compressors are further subdivided into different categories depending on their power ratings.

Probably you have heard of small rotary screw air compressors and large ones. The difference is usually in terms of their power ratings.

You can choose to buy a 5hp rotary screw air compressor, 7.5hp rotary screw air compressor 10hp rotary screw air compressor 15 hp rotary screw air compressor and even bigger compressors such as 20hp rotary screw air compressor 30hp rotary screw air compressor and 50hp rotary screw air compressor.

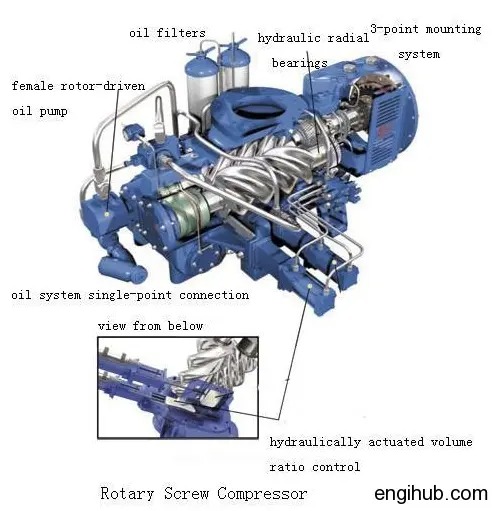

Components of Rotary Screw Air Compressor

1. Rotors/Rollers

This component is usually considered as the heart of a rotary screw air compressor. Whether you are buying a brand new or a used rotaryair compressor, you should ensure that the air ends are present. This is the component through which air is compressed. A stream of air enters the compressor through an inlet valve. It is then mixed with some oil as it undergoes the compression process.2. Compression Cylinder

The compression cylinder is a component that houses the roller. The airstream that has been collected is channelled through the chambers of the cylinder then into the spinning rotors. The amount of cylinder in a unit will determine the number of stages and the amount of pressure to be generated.3. Air filters

The air filters are positioned right at the opening of the compression valve. They filter dust, moisture and other solid particles that are likely to cause some mechanical damage inside the system. Other air filters are positioned within the chamber components, and they do the same task of filtering solid particles.4. Oil filters

These components are found oil-lubricated rotary screw compressors. They are positioned inside the walls of the rotating chambers and near the discharge valves. They filter off the air that is being discharged from the compressed stream of air.5. Bearings

The bearings of a rotary screw air compressor are located on the ends of both the rotors. Their main function is to ensure that the rotors are in a stable and secure position. The bearings also ensure that the rotors rotate evenly and have a balanced load capacity. Naturally, bearings are designed to minimize the effect of friction on the air compressor. They come in different designs depending on the size and desired output of the air compressor.6. Motor

The motor is responsible for powering the rotation of the rotors. You can adjust the power settings of the motor so that it can affect the rate of rotation.7. Discharge valve

The discharge valve is positioned at the extreme end of the suction valve. It signifies the end of the air compression cycle. This valve receives air that has low pressure and releases it to the holding tank. It can also discharge this air for its relevant application.8. Control system

Just as the name suggests, the function of the control system is to control the operation of the rotary screw air compressor. You can use it to determine the output that you intend to get from the system. The control system has a display monitor which you can use to gauge the performance of other air compressor components. Well, these are the main rotary screw air compressor parts. However, you can find customized rotary screw air compressor, which is likely to have extra components. For instance, you can easily buy a used rotary screw air compressor with dryer.Applications of Rotary Screw Air Compressor

An articulately cut metal sheet. A wooden load up that mirrors a decent idea or aviation save the part that makes an ideal plane.

Exactness, precision, and master building go into the creation of helpful parts, devices, and other creative products you see around yourself.

What’s more, what goes behind the thinking about these items?

All things considered, with regards to making flawless creations, “Laser Cutting” has consistently been an extreme strategy.

Laser engraving machines can cut the most multifaceted shapes quicker than some other instruments. Furthermore, a large portion of the great quality laser cutting machines has been perfectly curated for different applications.

In the event that you are into laser cutting business, you should think about various laser cutting applications and their degree. Tell us about every last one of these applications in detail.

Here is a brief overview of the most common applications of air compressor for laser cutting machine:

1. Metal Sheet Cutting

Metal sheet cutting the greatest and the most broadly perceived applications of laser cutting.

Through laser cutting, it is conceivable to cut metals like steel, aluminum, metal, tungsten, and nickel. Anyway, what occurs during metal sheet cutting?

A laser beam is centered around the outside of the metal.

The metal at that point absorbs the beam, melts, and takes the ideal shape.

On the off chance that you need clean cuts and smooth finishes, you can still go ahead and do so with the post-laser processes.

2. Signage cutting

As per different promoting reports, signage will make the most noteworthy print application in recent years. many people are expected to embrace signage.

Signage manufacturing companies need laser cutting to make 3D signage boards out of wood and plastic. Furthermore, laser machines have all the adaptability one needs to engrave various signage designs.

For making an ideal laser cut signage, experts must guarantee that the measurements are pre-characterized and right.

Air-assisted laser cutting with signage laser parts is known to give an ideal, proficient, and modified cut. The last size obviously, relies upon the client.

The compressed air can also ensure that the signage has a smooth finishing.

3. Glass cutting and engraving

That glass looks extremely beautiful! Have you ever found yourself making this statement?

If the answer is yes? Then you probably are delighted by the work of compressed air for laser cutting machines.

Most glasses that are used in different application areas are cut and engraved through laser cutting.

Glass mugs, wine glass, and other artifacts that are made of glass material must have undergone an intricate laser engraving process.

This applies to other glasses that are used in large scale applications such as construction.

4. Plastic cutting

Although cutting plastics may seem to be a simple process, there are times when you need to be more careful, especially when dealing with high-density plastic materials.

Compressed air for laser cutting is also deployed when you want to improve the accuracy of the plastic cutting. It is usually not easy to achieve precise cutting when using different techniques.

Laser cutting is also safe for cutting the plastic materials as it limits the burning effect. There will also be minimum pollution on the environment.

The cutting can also be used for engraving and adding labels onto the plastic materials.

Applications of Rotary Screw Air Compressor

Planning to buy the best rotary screw air compressor? That is okay. But what do you intend to use it for?

Here are the main applications of a rotary screw air compressor

-Textile industry: Rotary screw air compressor has numerous applications in the textile industry. This applies to both oil-free and oil-injection rotary screw air compressors.

-Electronics: Most electronics, including those used for telecommunication, use rotary screw air compressors.

-Iron and steel industries: Manufacturers dealing with metals such as iron and steel tend to use rotary screws for various applications.

-Food and Beverage: Machines used for processing food and beverages have rotary screw air compressors which guarantee their efficiency. In this case, an oil-free rotary screw air compressor is mainly used for such applications.

-Chemical industry: Machines used for processing chemicals including petrochemicals have air rotary air compressors.

-Drugs and medicine: Since drugs and medicines are very sensitive to chemicals, oil-free rotary screw air compressors are used for ensuring that the machines run smoothly and efficiently.

There are many other applications of this air compressor pump. As you can see on this list, the device is used for different applications, whether small or large.

What matters is the specifications of the rotary screw air pump.

Why Should I Buy a Sollant Rotary Screw Air Compressor?-Advantages

Still not sure whether to buy the best rotary screw for whichever area of application? We are here to convince you.

Here are some of the advantages of Sollant rotary screw air compressor;

- A continuous flow of air: Rotary screw air pumps have what we call a 100% duty cycle. This simply means that they allow a stream of compressed air to flow continuously and consistently.

This is the main advantage, and it separates this rotary screw air pump from other types of air compressors.

- Large quantities of air: The design of the Sollant rotary screw air compressors allows them to pump large streams of air at a time.

This explains why they are ideal air compressors for large-scale applications.

- Long lifespan: Sollant rotary screw air compressors are manufactured to precision. We pay attention to the finest details of the pump.

Each component of the air compressor is made of high-grade material that will last you for a long time.

- Quiet operation: Unlike other types of air compressors which are known to be noisy, rotary screw air pump operates quietly. They rarely produce noise that can be sound pollution.

- Energy-efficient: Rotary screw air pumps consume a very minimal amount of electric energy. This is in comparison to other types of air compressors which are known for their high consumption of electricity.

- Irresistible warranties: When we specifically narrow down on the Sollant rotary screw air compressor, you are bound to enjoy exclusive warranties.

This is an assurance that we fully trust the quality and functionality of the air pump.

Although the initial price of a rotary screw air pump may seem to be high, the benefits that you stand to gain are too good to ignore.

Since this high-tech air compressor will reduce the cost of operation, you still stand a chance to get back your investment.

Which is the Best Rotary Screw Air Compressor?

Since a rotary screw air compressor is an important device, you will always focus on getting the best out of your money.

But how do I buy the best compressor?

The first thing that you should consider is the area of application.

Where are you going to use the rotary screw air pump?

This is where issues such as oil-injected rotary screw air compressor vs oil-free rotary screw air compressor come in.

You cant use an oil-injected compressor in sensitive applications such as food, beverage, and chemical processing.

You should also consider the price of the rotary screw air compressor. How much are you willing to spend just to cater to the cost of the compressor?

However, you should not be overshadowed by the cost of a rotary screw air compressor. Doing so can push you into making a bad decision.

How to choose the best air compressor

Rotary Screw Air Compressor Manufacturer

So, where to buy the best rotary screw air compressor?

It is important that you buy from the best rotary screw air compressor manufacturers in China.

It is only from the best manufacturer that you can be sure about the quality of the compressor that you will get.

So, take your time to go through the list of rotary screw air compressor manufacturers before making that final decision.

In conclusion, I hope that this guide will help you to choose the best rotary screw air compressor.

In case you have any questions, feel free to seek clarification.

References